R01

© WIAC Ltd 2017. WIAC Ltd, Registered Office: Stoneygate House, 2 Greenfield Road, Holmfirth, Yorkshire,HD9 2JT UK

Reg: 6664171 VAT No: GB939454778

WIAC Ltd are capable of creating software and control system designs

for a variety of applications, both the novel and more mundane.

Some applications are transferable across multiple industries, some are

specific to a particular industry, process or plant.

An application may involve a single machine, a small sub process on a

line or the whole process line.

Applications include

• Batch Weighing

• Continuous Weighing

• Extrusion

• Ingredient Feed

• Recipe Handling

• Dust Extraction

• Vacuum Ovens

• Steam Tunnels

• Bin Banks

• RFID

Materials and Ingredient Handling

Materials and ingredient handling can include anything from material intake, transport, dispensing and feeding, combining and mixing to packaging and distribution. WIAC Ltd have provided solutions for processes including both dry and wet ingredient transport, weighing and feeding applications. These solutions also include recipe handling and processing.

Batch & Continuous Processing

WIAC Ltd have provided weighing and metering solutions for both batch processes to S88 and continuous processes. WIAC Ltd have also been involved hybrid processes, for example the make up of powder and liquid ingredient batches for continuous feed to an extruder for continuous downstream processes. These applications include powder dispensing stations, bin bank systems and liquid make process.

Complex Controls

From complex cascaded temperature control loops in specialised applications to gas dilution control. From rapid pressure changes to ultra slow oxygen solution control loops. These applications have included split range, switched output, scheduled output loops, cascade and dual (coarse/fine) loop controls.

Pump and Compressor Applications

WIAC Ltd. have provided solutions for the control of pump, compressor and blower sets in a variety of duty/standby configurations (duty/standby/assist, duty/assist/assist, etc.). These sets have been in variable speed, fixed speed and a mixture of fixed and variable speed configurations. These applications have included gas turbine driven compressors to diesel driven reciprocating compressors. From multiple pump water flow control, to scheduled output blower controls.

• Chemical Dosing

• Biological Nutrient Removal

• Anerobic Digestion

• Blower Controls

• Gas Turbine Controls

• CHP/Cogeneration

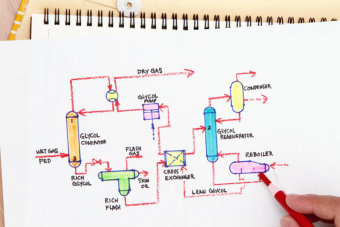

• Gas Dehydration Plant

• Pumping

• Compressors (Gas Turbine, Diesel, Electric)

© WIAC Ltd 2016.

WIAC Ltd,

Registered Office: Stoneygate House,

2 Greenfield Road, Holmfirth,

Yorkshire,HD9 2JT UK

Reg: 6664171 VAT No: GB939454778

WIAC Ltd are capable of creating software and

control system designs for a variety of

applications, both the novel and more mundane.

Some applications are transferable across

multiple industries, some are specific to a

particular industry, process or plant.

An application may involve a single machine, a

small sub process on a line or the whole process

line.

Applications include

• Batch Weighing

• Continuous Weighing

• Extrusion

• Ingredient Feed

• Recipe Handling

• Dust Extraction

• Vacuum Ovens

• Steam Tunnels

• Bin Banks

• RFID

Materials and Ingredient Handling

Materials and ingredient handling can include anything from material intake, transport, dispensing and feeding, combining and mixing to packaging and distribution. WIAC Ltd have provided solutions for processes including both dry and wet ingredient transport, weighing and feeding applications. These solutions also include recipe handling and processing.

Batch & Continuous Processing

WIAC Ltd have provided weighing and metering solutions for both batch processes to S88 and continuous processes. WIAC Ltd have also been involved hybrid processes, for example the make up of powder and liquid ingredient batches for continuous feed to an extruder for continuous downstream processes. These applications include powder dispensing stations, bin bank systems and liquid make process.

Complex Controls

From complex cascaded temperature control loops in specialised applications to gas dilution control. From rapid pressure changes to ultra slow oxygen solution control loops. These applications have included split range, switched output, scheduled output loops, cascade and dual (coarse/fine) loop controls.

Pump and Compressor

Applications

WIAC Ltd. have provided solutions for the control of pump, compressor and blower sets in a variety of duty/standby configurations (duty/standby/assist, duty/assist/assist, etc.). These sets have been in variable speed, fixed speed and a mixture of fixed and variable speed configurations. These applications have included gas turbine driven compressors to diesel driven reciprocating compressors. From multiple pump water flow control, to scheduled output blower controls.

• Chemical Dosing

• Biological Nutrient Removal

• Anerobic Digestion

• Blower Controls

• Gas Turbine Controls

• CHP/Cogeneration

• Gas Dehydration Plant

• Pumping

• Compressors (Gas Turbine, Diesel, Electric)